PROFILES

The profiles in the Comfort Line range are extruded from 6060 BUILDING QUALITY alloy, which has stricter impurity tolerances than the standard.

PROTECTION

Chemical anodisation with the "QUALANOD" label, natural colour and bronze colour. Profiles in stock are available with a class 20 anodised finish (20 to 24 microns).

By polyester powder coating with the "QUALICOAT" label, Seaside mention, and the "QUALILAQUAGE" and "QUALIMARINE" labels. The minimum thickness of the lacquer is 60 microns for continuously visible surfaces.

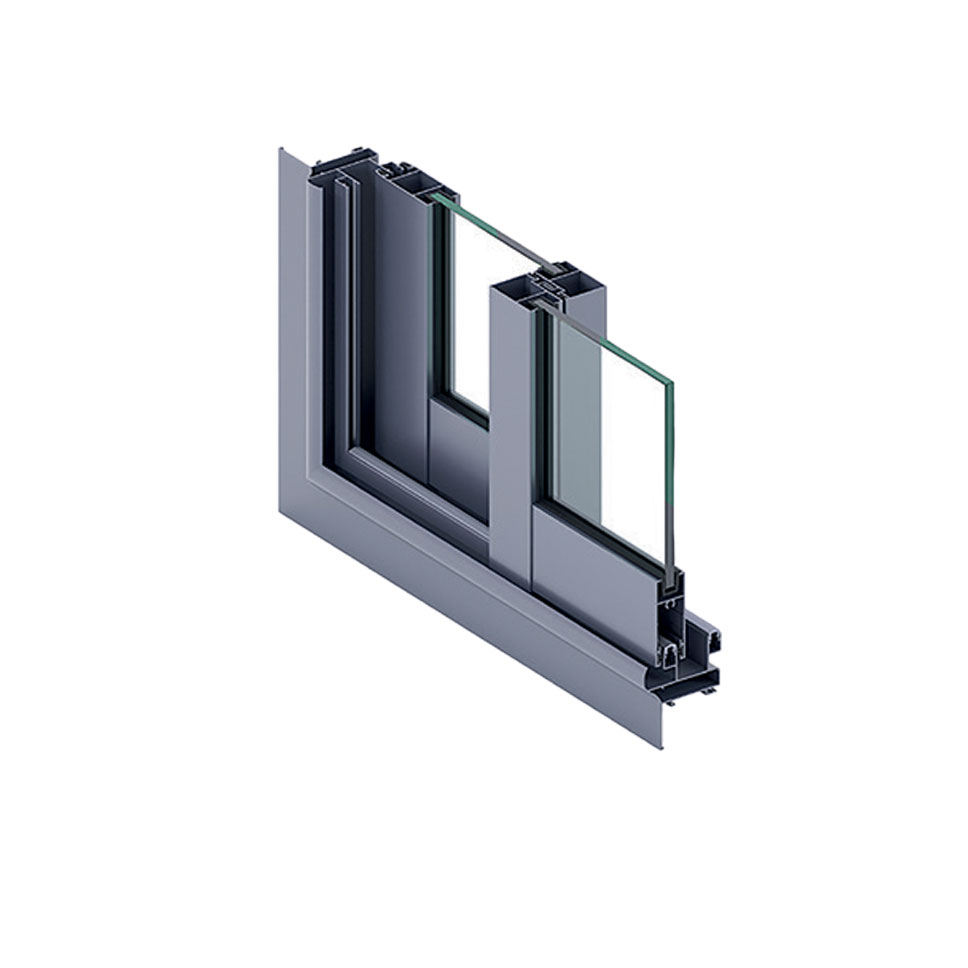

FRAME

Tubular (2 and 3 rails) with rounded shape on the inside and outside, with the option of clipping on the joint cover and drip cap. Mitre joint assembly.

Side and centre panels are rounded and tubular in shape. They are available in single or reinforced versions depending on the size and exposure of the structure. The crossbars allow for straight joint assembly using stainless steel screws.

ASSEMBLY

Frames: mitre cut using angle brackets.

Openings: straight cut using stainless steel screws in alvéovis.

All assembly parts are made of aluminium or stainless steel.

Sealing between the different profiles is ensured by brush seals.

Glazing: 6 mm. Fold-over assembly using EPDM seals, weatherproofing in accordance with DTU 39.

ROLLERS

- Ball bearing rollers

- Single rollers, pressure screw assembly

- Easy disassembly in accordance with standard 24301

The maximum permissible glazing loads are 50 kg/leaf depending on the configuration selected.

CLOSURE

1 locking point per single or double shell with the option of locking from the outside with a key.

RECOMMENDED DIMENSIONS

For a 2-leaf sliding door:

Width 2400 mm

Height 2200 mm

For larger dimensions, please consult us.